Technical Article

Published 03/2017

Reclosing 101

The valuable secrets of using Reclosers on Modern Distribution Networks

Over the course of the last few decades, Distribution Network Service Providers (DNSPs) have played witness to the incredible worldwide proliferation of Automatic Circuit Reclosers (ACRs). A seemingly simple technology of automatically closing circuit breakers after interrupting a fault is brutally effective in increasing network reliability. The economic and safety benefits of deploying these network assets is well documented.

There are countless utilities around the world who have spent valuable resources on deploying reclosers, but then see their balance sheet improve in the very same year the device is deployed. From an economic standpoint it makes sense, but we are interested in understanding how best to make the most of our engineering installation. It is certainly worth exploring the rationale involved in the actual configuration of ACRs to reach the best possible value from their deployment.

In the heady old days of network maintenance, a utility operator would often receive a dispatch call to visit a field circuit breaker which has tripped. The first instruction would be to look for any obvious cause of a fault, but then proceed to reset the relay and close the breaker. Cautiously, the operator would go about his task, reset the relay and close the breaker, but to his utter bewilderment the circuit breaker would close and no fault current would be present. Was this a nuisance trip? Was it mechanical failure? Did the relay fail?

The answer to these questions was almost invariably no. The true diagnosis is that the vast majority of distribution network faults caused by transient effects, to the tune of up to 80% of faults. The reality is that most circuit breaker operations should only be temporary. Furthermore, the entire time that it took to drive out to the circuit breaker installation site, customers' supply lines were cut and the utility was effectively shredding its income. There is a tremendous amount of value that can be captured simply by automating this restoration process. Automatic Circuit Reclosers are the industrial revolution of the distribution network, automating what used to take hours into mere seconds.

“Very well”, mutters the engaged reader, “but what do I actually set my Autoreclosing times to be?”. The truest answer is “it depends”, but we are willing to explore some of the rationale and guidelines behind this configuration.

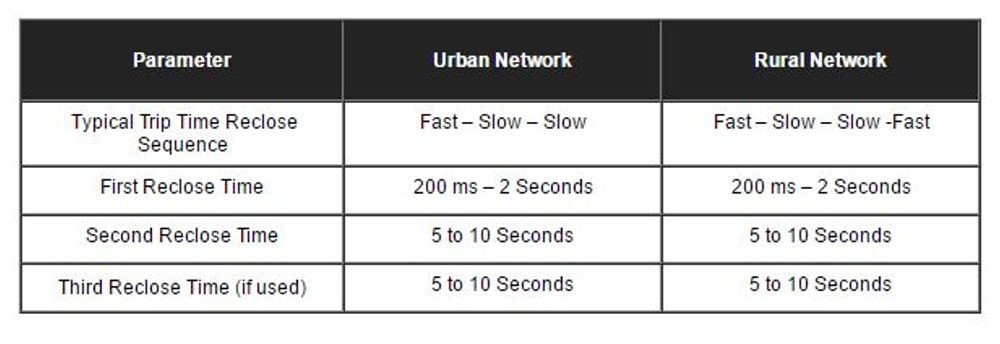

We can begin with the simple truths – any sequence of recloses can, at the most, be a total of four shots to lockout. This is four trips, and three recloses. We make the differentiation between an “Open” state and a “Lockout” state, in that “Lockout” implies “Breaker is open without any automatic pending close”. The first golden rule is that the “dead time/open time/autoreclose time” is to allow the fault to clear. This time is selected based on the expected type of fault that is to be cleared.

Let us first consider the case of the rural overhead network. In the case of the rural overhead network, lightning is the most common fault, followed by vegetation collisions. Since lightning is exceptionally quick, the first trip of a rural ACR is typically as fast as possible. This is to interrupt the fault as quickly as possible before damage is caused to the network.

After this first interruption, the following dead time needs to be long enough for the ionized gas caused by the lightning strike or flashover at the fault location to dissipate. This would typically be two seconds or less. If this first reclose is too quick, the ionized gas could cause a restrike of the fault.

Since the first trip in our sequence is for lightning strikes, if the ACR then recloses onto the fault we can declare with a fair degree of confidence that the fault was not caused by lightning. At this point, the next most likely candidate is that there is some other sort of foreign body on the network such as an animal or a tree branch. This is the reason that the second and third trips in a reclose sequence are usually slower Inverse Time Delay curves, usually of the ANSI or IEC standardized variety. These slower curves allow fault current through the recloser for a short time interval to quite literally burn the fault off the network. These inverse time curves trip faster on higher fault currents and slower on low fault currents, effectively acting as an equipment stress threshold that allows for the maximum energy to be delivered to a fault location to attempt to burn off the fault without causing physical damage to the network. Since we are providing energy to the fault, the second and third reclose times typically tend to be longer (in the 5 to 10 second range), allowing time for the incinerated debris to fall away from the line.

Most often if a reclose sequence makes it past the third trip, the fault is likely to be a permanent bolted fault, at which point reclosing does very little anymore and field service becomes genuinely necessary. If the recloser trips three times, utilities generally set their ACRs to go to lockout, or conduct one final fast trip attempt. However, at this point in the sequence we are clutching at straws and it is probably time to send the team out to find out what happened out on the distribution line.

The sequence in the city is similar, but there are a few key differences. In general, in city areas where buildings are higher than the power lines, the most common transient fault is less likely to be a lightning strike and more likely to be a foreign body on the network. In built up areas, the most common deployment is a three shot to lockout system with a first fast trip. The reclose times are in line with what is deployed in the countryside.

Furthermore, in urban areas utilities often forego the use of SEF and simply set it to a single shot to lockout. This is due to the likelihood of SEF being triggered by conductors lying on the ground, and this risk is of course much higher in an urban environment. There is not much use in reclosing on SEF in an urban environment when the suspected reason would be a cable on the ground.

“Autoreclosing is one of the earliest forms of Distribution Network Automation,” reports NOJA Power Group Managing Director Neil O’Sullivan. “Even in today’s extensively automated Smart Grids, Autoreclosing is still one of the most effective forms of automation an Electricity Utility can deploy today.”

To sum up our discussion, the principles behind configuring Auto Reclosing and the associated timing arises from the practicality of running a distribution network. Whilst every situation has its own unique merits making “cookie cutter” standard settings difficult, with a little forethought and field experience it is possible to achieve significant reliability and economic advantages with some fairly simple settings.

If you still have unanswered questions about recloser rationale, it may be worth your while to give the team at NOJA Power a call. NOJA Power have been manufacturing Automatic Circuit Reclosers for many years and have decades of experience in outdoor circuit breakers– they would be delighted to share some of their experience to assist you in achieving a safer and more reliable distribution network for yourself and your dependent customers.

Want to stay up to date with Electrical Distribution Technology?

Join our list for a free weekly technical bulletin, as we share our Global Electrical Engineering experience directly to your inbox.

Subscribe →